-

71 Avenue DE LA PATINIÈRE

38500 VOIRON

-

Mon - Thu

7h - 19h

Fri.

7h - 12h

-

Call us

Discover COFIM SYSTEM

Since 1986, COFIM SYSTEM favours innovative technical solutions, from design to manufacturing. Specializing in cold machining of tubes and pipes, the company has created a complete range of machines dedicated to cutting and bevelling for various sectors of industry. COFIM SYSTEM has an Engineering Department with recognised experts in mechanical and Mechatronics, and manufacturing of special CNC machines tools allowing us to propose solutions based on standard hardware, but also with the capability to develop machines whose innovative design meets the specific requirements of our customers.

35

Years of experience

3 000

Machines delivered

200

Special machines manufactured

50

Country covered

Download the full catalogue

All machines, services and data solutions available on e-version.

Cofim product range

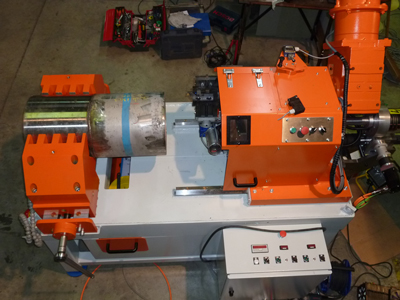

Cutting

Cutting, bevelling and counterboring a pipe with the cold cutting split frame CTO and CTNO serie. The best, confortable and safety solution.

Bevelling

Prepare welding more effectively with COFIM bevelling machines type TU 2-3-5-6-12-14 equipped with form-tools or with the Alpha® Module for an electronic machining.

Facing

To machine thin-wall pipes quickly, precisely, without leaving mark or burr with portable COFIM SYSTEM facing machines type DE & TUDC.

Flange facing

Flange facing with inside or outside clamping with COFIM SYSTEM CTO-FF & TU-FF machines, enable mechanical or digital stroke with the Alpha® Module.

Special machine

Meeting specific needs of national and international customers is the mission of the COFIM SYSTEM R&D department engineers, who have developed and assembled over a hundred special machines so far.

Contact-us

Your contact details will allow us to answer you quickely

Monday - Thursday : / Friday :

Your questions, our answers

Cofim machine as an option can be equipped with insert carbide toll holder available on the market. We spend a lot of time and money, we make tests in order to improve new material and try to reduce the cost of the consumable.

With ATEX certification, the cold cutting TYPE CTO COFIM SYSTEM machines meet the requirements of no explosion issued by the oil and gas industry.

Our international network can directly answer to you. We run a quite extensive distributors network around the world. Call the seller in charge of the aftersales service in his country and we will be very pleased to help you.

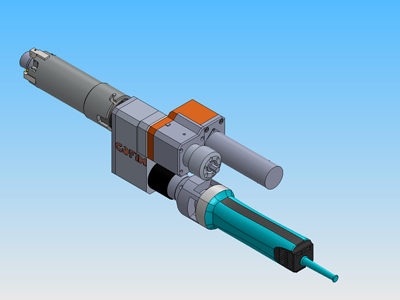

Cofim SYSTEM offers 2 solutions :

- In case of standard equipment : the pipe beveling or cutting machine producers propose dedicated tool bits for the bevel form. You need to change the tool bits each time you change the form.

- With the innovative solution Alpha module ®, a CNC control program,the bevel form is given by the electronic device which drive the different machining axis to give the final form. With a simple standart carbide insert, Cofim SYSTEM is able to perform all bevel forms without any tool bits change. One carbide insert for all forms. welcome in the mecatronic world !

All machining axis can be driven through a digital screen, control box and video camera. In case of high radioactivity, certain electronic device can’t work on this area, Cofim SYSTEM use different kind of drive able to resist to this aggressive environment.

With the alpha module ® solution we brake the limit. We works like a lathe, with single point system driven by electric motors. Step by step process with high speed rotation makes the machines ligther and versatile. We machine 45 mm with a standard TU6 and 110 mm with a CTO1200 but the drive was hydraulic. Every WT and material are now possible with Cofim machines.

Our customer voices

News

3 Nov

SCHWEISSTEC STUTTGART 2019

COFIM ON SCHWEISSTEC EXHIBITION STUTTGART HALL 10 STAND 1005

Lire la suite

15 Apr

TUBE® - Düsseldorf

We will be on TUBE Düsseldorf, from April the 16th to the 20th with 2 major news :

-...

2 Nov

FABTECH - Chicago

COFIM will be present on FABTECH Chicago from 6th to 9th November on Polysoude / IGM booth (B19061)...